Modern traffic cameras rely heavily on artificial illumination. Infrared emitters and visible flashes are used to ensure license plates remain readable in low light, at speed, and from multiple angles. It is within this technical context that antiradar stickers behave differently from ordinary surface materials.

Unlike decorative or protective films, these materials are engineered to interact with high-intensity light in very specific ways. Their behavior is not based on opacity or tint but on how light energy is redirected at the moment of exposure. This distinction explains why results under camera flash often differ dramatically from what the human eye perceives.

Understanding this interaction requires looking beyond surface appearance and into optical structure.

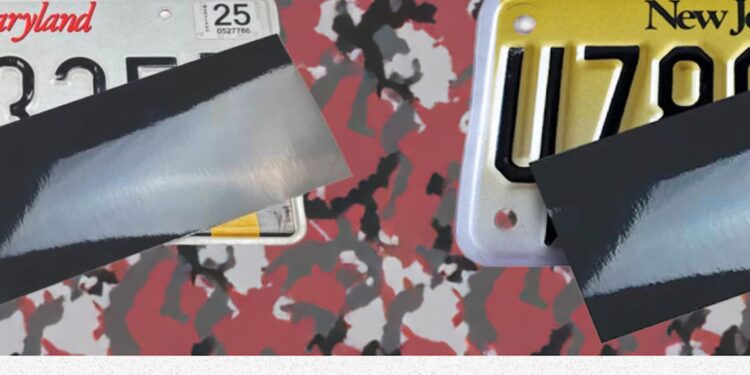

Anti Radar Sticker Number Plate Materials Explained

An anti radar sticker number plate – https://alitehub.com/pages/antiradar-stickers-for-license-plate solution typically uses layered optical elements rather than a single reflective coating. These layers are designed to respond to sudden bursts of light, such as camera flashes or infrared illumination.

At the core of these materials are micro-structured surfaces or nanofilm layers. When intense light hits the plate, the structure disrupts the normal reflection path. Instead of bouncing light evenly back toward the camera sensor, the material scatters or redirects it, often causing glare or overexposure.

Key optical characteristics of these materials include:

- controlled light scatter rather than uniform reflection

- selective response to high-intensity illumination

- minimal visual impact under normal daylight

- dependence on flash angle and wavelength

This engineered response explains why the plate can look normal to the naked eye while appearing distorted or unreadable to a camera.

Anti Radar License Plate Sticker vs Conventional Reflective Surfaces

A standard reflective license plate is optimized for legibility. It reflects light back toward the source to ensure numbers are visible at night. An anti radar license plate sticker deliberately alters this behavior.

Instead of retroreflecting light cleanly, the material introduces optical noise. This noise overwhelms the camera sensor during the brief exposure window created by the flash. The result is often a bright flare, bloom, or loss of contrast in the captured image.

Differences between conventional reflective plates and anti-radar materials include:

- standard plates enhance contrast, anti-radar materials reduce it

- conventional surfaces aim for clarity, anti-radar layers introduce distortion

- traditional reflection is uniform, anti-radar reflection is directional

These differences are subtle in appearance but significant in how cameras interpret the image.

Anti Camera Sticker Behavior Under Flash Conditions

An anti camera sticker is designed around timing. Traffic cameras capture images in fractions of a second, relying on synchronized illumination. Anti-radar materials exploit this by reacting most strongly during that brief flash interval.

The effectiveness of this interaction depends on several variables. Flash intensity, wavelength (infrared vs visible), camera angle, and distance all influence how the light is scattered. Because of this, results can vary between different camera systems.

Factors influencing flash interaction include:

- camera flash power and duration

- infrared versus visible light usage

- mounting angle of the plate

- quality and precision of the optical layer

This explains why high-quality materials demonstrate more consistent behavior across different camera setups, while lower-grade products may perform unpredictably.

License Plate Film Cover Technology and Alite Nanofilm

A license plate film cover based on nanofilm technology represents a refined version of these principles. Instead of relying on thick reflective layers, nanofilm structures operate at a microscopic level, interacting with light wavelengths directly.

Alite Nanofilm is an example of this approach. The material is engineered to remain visually unobtrusive while maintaining a controlled optical response under flash and infrared exposure. The emphasis is not on visible alteration but on precise light management during camera capture.

Because the optical behavior is embedded within the material structure, performance remains stable over time. There is no reliance on surface coatings that can wear unevenly or degrade unpredictably. This consistency is a defining characteristic of advanced nanofilm solutions.

The way reflective anti-radar materials behave under camera flash is rooted in physics, not illusion. Antiradar stickers are engineered to exploit the brief, intense illumination used by automated systems, redirecting light in ways that overwhelm camera sensors without altering daytime appearance.

An anti radar sticker number plate solution differs fundamentally from conventional reflective surfaces by introducing controlled optical disruption rather than clarity. This is why results under flash can vary so dramatically compared to normal viewing conditions.Technologies like Alite Nanofilm illustrate how this field is evolving toward precision engineering rather than simple reflectivity. As camera systems become more advanced, materials that interact intelligently with light—rather than merely reflecting it—are likely to play an increasingly important role in how license plates are perceived by automated infrastructure.