Corrosion is a normal thing that happens to metal structures as time passes. This causes big difficulties for industries which depend on metal for building and making things. The harm from corrosion can result in structure collapse, safety dangers, and expensive fixes. Knowing ways to stop corrosion in metal structures is very important for making them last longer and stay dependable. Now, let us look at ways we can prevent corrosion and make sure metal structures stay strong.

Understanding Corrosion

Corrosion is a result of reaction between metals and things in the environment like oxygen, wetness or chemicals. When this reaction happens it makes oxides or other compounds that cause metal to become weak. Things such as dampness, hotness, dust particles along with being near to chemical substances can quicken the process of corrosion. Iron and steel are prone to corrosion, so it is very important to take steps for preventing this in places where these metals are commonly used.

Material Selection

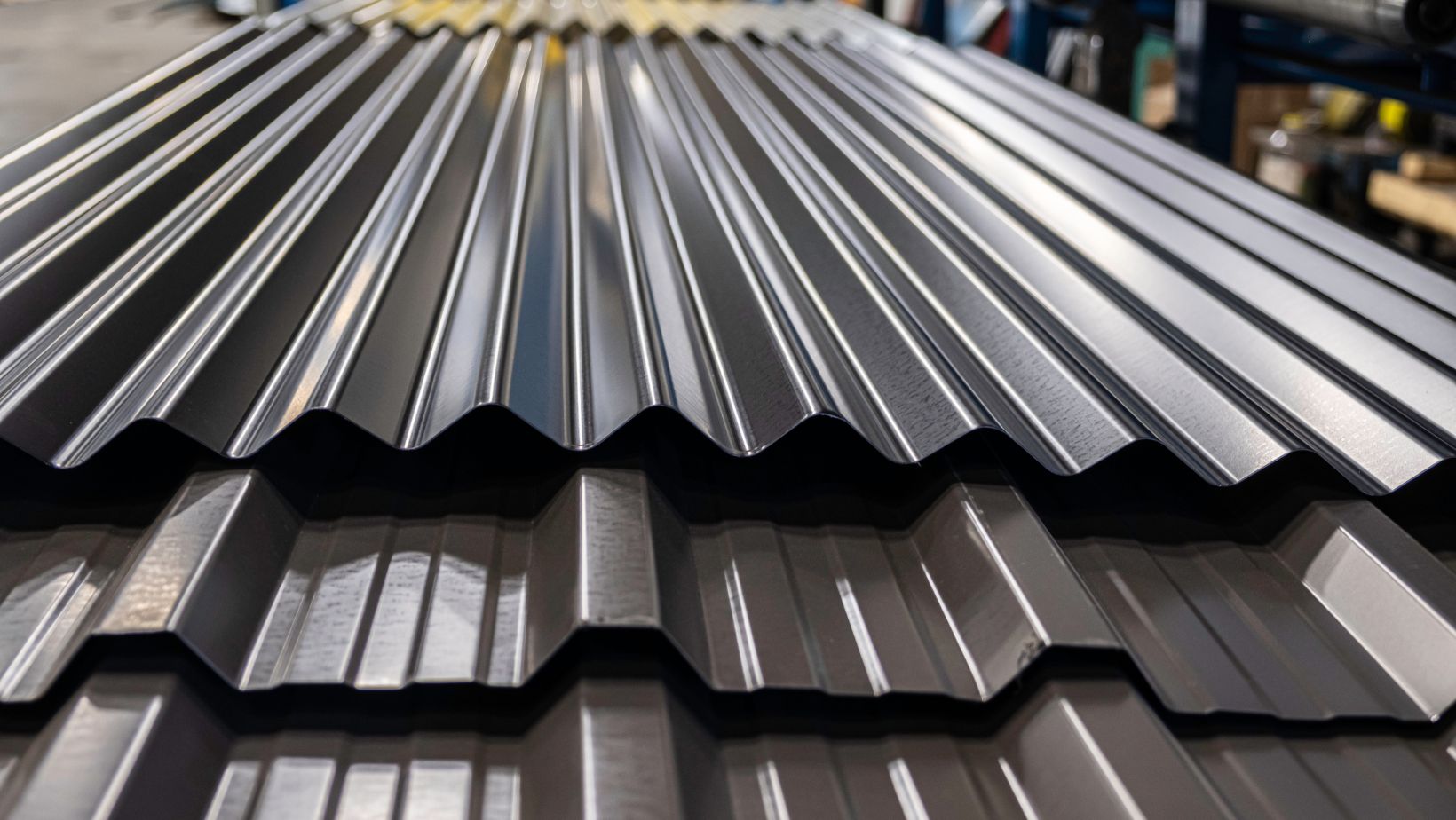

Selecting appropriate materials is an initial method to avoid corrosion. For structures that will be in tough surroundings, it’s best to pick metals that have built-in corrosion resistance like stainless steel and aluminum. Stainless steel, for instance, has chromium included in its composition and this element creates a safeguarding oxide layer on the surface which stops any additional oxidizing process from occurring. For steel applications, the addition of coatings or galvanization to steel tubing can provide extra protection from corrosion.

Protective Coatings

Applying protective coatings is a way to safeguard metal surfaces from elements that cause corrosion. Coatings such as paint, powder coatings and special anti-corrosion coats form a layer stopping moisture and oxygen from touching the metal surface. It is important for people to often maintain and reapply these coverings so they can keep on giving protection. Furthermore, improvements in coating technology have resulted in the creation of high-quality coatings that can endure for longer periods under very tough circumstances.

Cathodic Protection

The method of cathodic protection uses an electrochemical cell where the metal surface to be protected becomes the cathode. To do this, a “sacrificial” metal that easily corrodes is connected – for example zinc or magnesium.

Environmental Control

Lessening the humidity, managing temperature and controlling the contact with corrosives are all ways to control the environment around metal structures. This can help protect their surfaces from corrosion. In industries, using dehumidifiers, good ventilation and inhibitors for corrosion can make an environment less suitable for corrosion. A corrosion control plan must include regular checking of environmental conditions and taking actions for corrections.

Design Considerations

To make metal structures last longer, we can plan protection from corrosion during the design stage. Design methods include not using places where moisture could gather like crevices and joints, making sure there’s good drainage and selecting materials that resist corrosion in important areas. Also, creating designs that are easy to inspect and maintain allows for quick identification and fixing of corrosion problems. Implementing these design considerations can significantly reduce the likelihood of corrosion-related failures.

Regular Maintenance and Inspection

Maintenance and checking regularly is very important to find out about corrosion problems early on before they turn into serious issues. Cleaning metal surfaces often so as to get rid of impurities, examining for signs of corrosion, and fixing harmed coatings or sacrificial anodes quickly are necessary maintenance actions. Establishing a complete maintenance plan with planned inspections and preventive steps guarantees the continued safeguarding of metal structures.

To stop corrosion in metal structures, we must use a mix of choosing materials, coatings for protection, cathodic safeguarding, control of environment and design which are thoughtful. Also regular maintenance is very important. By knowing the things that cause corrosion and doing these precautions, industries can make their metal structures live longer. This helps with safety too because it lessens the need for repairs and keeps costs low on upkeep work. The active method to protect from corrosion guarantees that metal structures stay strong and dependable even in tough surroundings.